Using Generative AI to Predict Demand and Optimize Inventory in Logistics.

Find how Generative AI boosts logistics by predicting demand, optimizing inventory, and cutting costs for smarter supply chains

9/1/2025

artificial intelligence

7 mins

The current era is all about making effective marketing and management strategies by predicting market demand trends to help stay one step ahead then your competitors. These rapid advancements have provoked businesses to consider the inclusion of a Gen AI solution for logistics management, which says a lot about its significance.

Gen AI solution for logistics management is no longer an optional add-on idea for business, but it's becoming a key to future success. Such a tool can serve as a single platform that analyzes market trends, makes predictions around demand and supply, and helps you strategize to maintain your inventory beforehand. Ultimately, helping you get an edge over your competitors, especially when the market is struggling.

With our article, we will help you explore the potential of Gen AI for logistic management, its impact, which Gen AI models can support it, its benefits, and challenges. So that your business can make a well-informed decision.

Gen AI in Logistics

Gen AI in logistics is an approach to revamp and optimize the traditional, inefficient inventory management process. This solution can automate a lot of manual processes, like analyzing the data trends, predicting the demand and supply, and accordingly making arrangements to maintain the inventory. In this way, we can have an intelligent solution that can automatically handle multiple tasks and take off major responsibility from your shoulders, so that you can plan intelligently.

Why is the Traditional Logistics Management System Insufficient?

Traditionally, logistics management is a very resource-intensive task that consumes both time and effort. For keeping a check on the inventory while actively looking and understanding market preference, sales, and profit trends to predict future market trends, businesses need to have a particular number of dedicated resources.

For small businesses, having enough team members dedicated to handling each task is difficult because of budget constraints. Also, the traditional system for logistics management can only handle one job at a time and often gets overwhelmed and tired. Here, a slight negligence or delay in execution could be a reason for you in failing to meet the business targets.

What is the Impact of Gen AI Solution for Logistics Management?

A Gen AI solution for logistics management emerges as a revolutionary idea to address the daily logistics needs of business owners. This solution can prove to be a single solution for handling multiple logistics-related challenges simultaneously, like data analysis, understanding market interest, making a strategy, and managing the inventory accordingly. It will also help businesses to maintain consistency while reducing costs and enhancing customer satisfaction. Eventually, this allows businesses to ensure optimal performance even if they have limited availability of resources in terms of people or budget.

Gen AI Models for Logistics Management Applications

Generative AI models transform logistics management by extending intelligent forecasting, automation, and optimization. All these models have their own specialized abilities to help businesses build resilient, efficient supply chains.

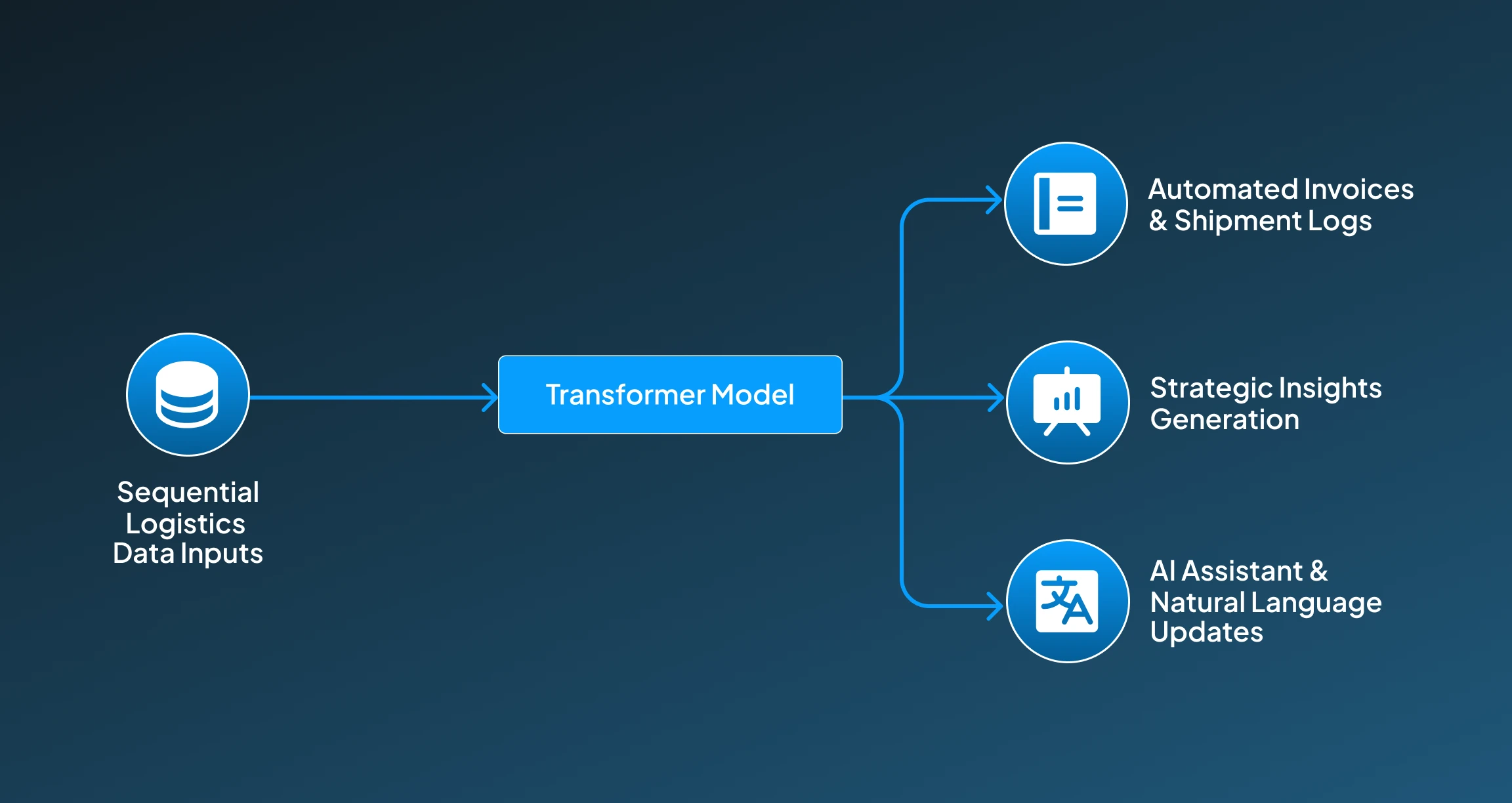

1. Transformers (e.g., GPT-based Models)

- How They Work: “Transformers are another type of Gen AI models that use attention mechanisms to analyze relationships in the provided sequential data, which helps them to generate text, summaries, and structured outputs.” (Ashish et al., 2023)

- Intelligent Logistics Communication Application: These transformers can be utilized for understanding relationships in a given sequence and generating text outputs accordingly. Such an application can be used for enabling intelligent automated communication like generating invoices and shipment logs, generating strategic insights from market and customer data, and powering AI assistants to handle customer queries and delivery updates in natural language.

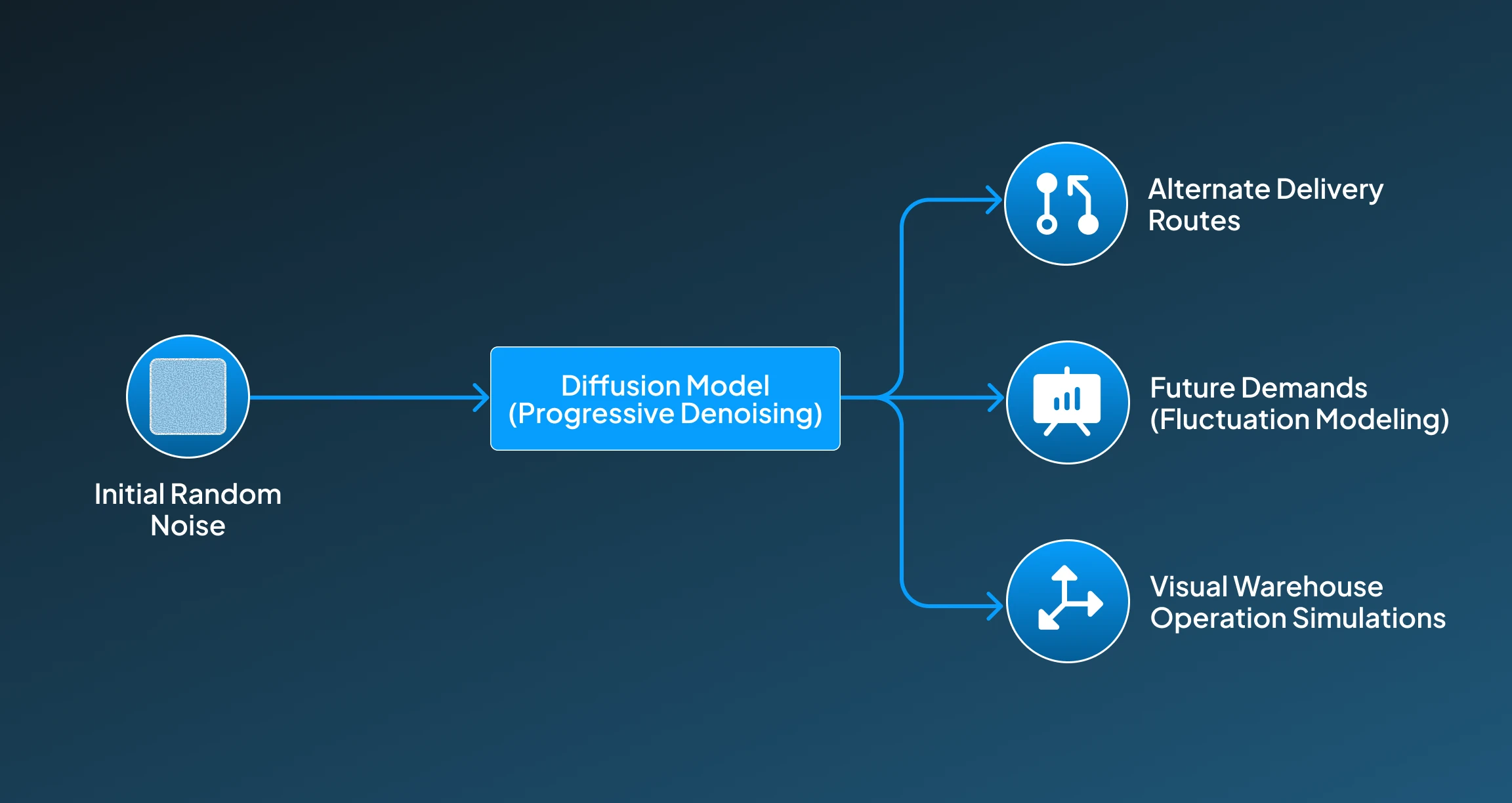

2. Diffusion Models

- How They Work: “Diffusion models start with random noise and gradually “denoise” it to generate realistic data samples, making them great for simulation and prediction.” (Florinel-Alin et al., 2025)

- Smart Logistics Simulation Application: Diffusion models work by starting with random noise and gradually denoising it to create realistic data samples. In logistics, they enable Uncertainty-Aware Logistics Simulation, where they can generate alternative delivery routes under traffic or weather constraints, model future demand fluctuations to test supply chain resilience, and create visual simulations of warehouse operations before real-world implementation.

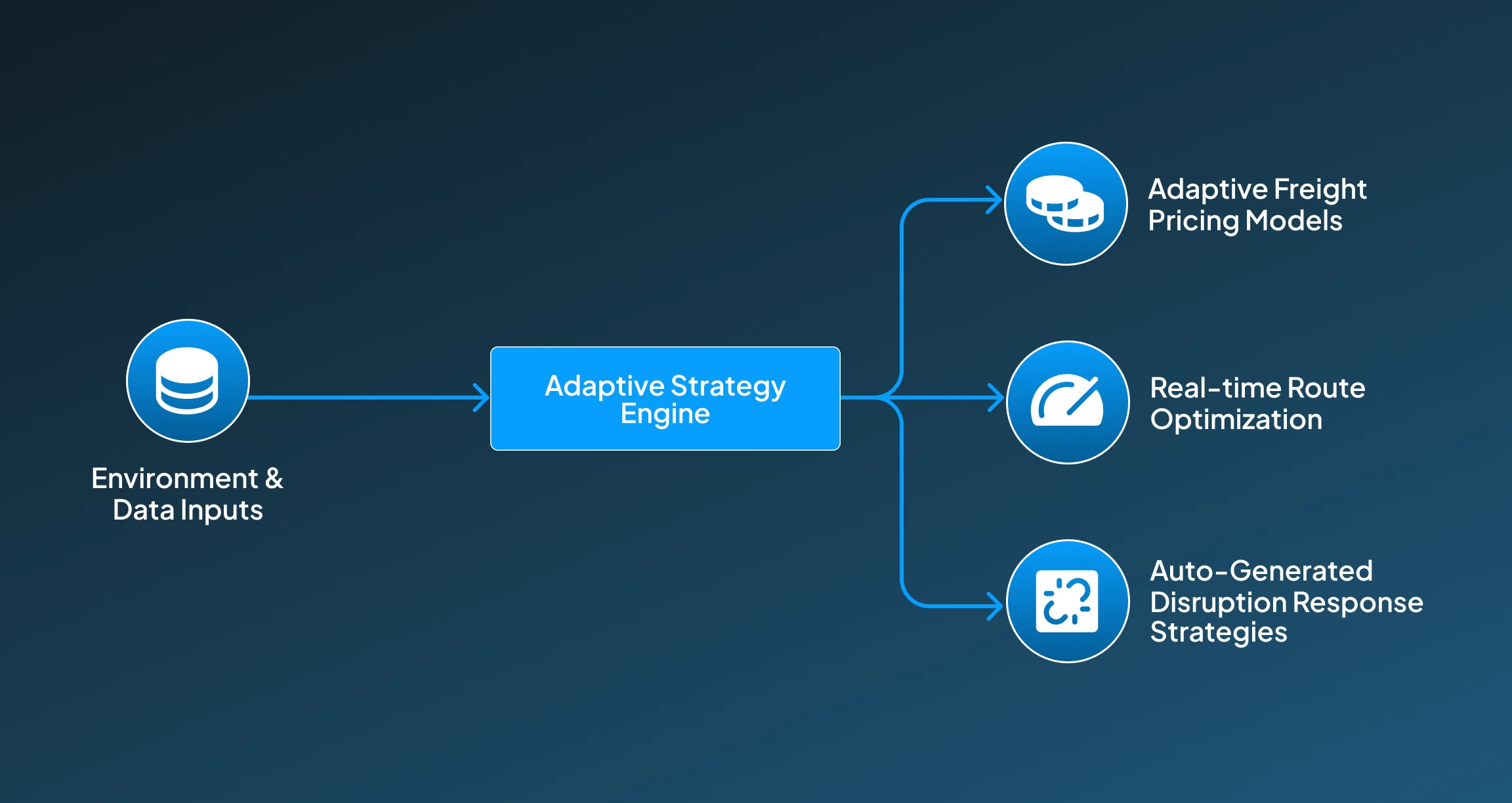

3. Reinforcement Learning + Generative Models

- How They Work: Reinforcement Learning (RL) in combination with generative AI models can be used for trial and error with rewards/penalties, and suggesting appropriate strategies for decision making.

- Adaptive Logistics Optimization Application: This combined approach can be used for generating adaptive strategies. In logistics, it can ensure adaptive logistics optimization, in which the system can test different freight pricing models, optimize routes in real time under changing conditions, and auto-generate strategies that respond to disruptions like strikes, natural disasters, or fuel price hikes.

Benefits of Gen AI in Logistics Management

Generative AI is transforming every field of life. For logistics, it is introducing enhanced decision-making, reducing inefficiencies, and helping build resilience.. Its applications aren't just restricted to automation; it offers measurable improvements in forecasting, cost control, customer satisfaction, and overall supply chain performance.

1. Improved Forecasting

Gen AI has the ability to analyze historical and eventually compute real-time data to more accurately predict demand, inventory needs, and supply chain fluctuations. This helps businesses stay prepared for market changes.

2. Operational Efficiency

A Gen AI solution can automate many routine repetitive tasks like documentation, shipment tracking, and route scheduling. By executing these responsibilities it significantly reduces manual effort, speeds up operations, and allows logistics teams to focus on strategic activities.

3. Cost Reduction

With such advanced and intelligent Gen AI solutions, businesses can experience AI-driven minimized fuel usage, reduced idle fleet time, and streamlined warehouse operations. Through it, businesses can cut down on unnecessary expenses while helping them maximize profits and resource utilization.

4. Risk Management

By simulating scenarios priorly, such a Gen AI solution helps businesses anticipate possible disruptions like traffic jams, strikes, or natural disasters. This assists them in making a proactive contingency plan and maintaining the supply chain continuity despite uncertainty.

5. Enhanced Customer Experience

Through such an optimized workflow, it allows businesses to ensure faster deliveries, real-time shipment updates, and personalized communication, eventually enhancing customer experience and trust.

Challenges of Generative AI in Logistics

While generative AI is reshaping logistics with automation and efficiency, it also introduces hurdles. Businesses must navigate these carefully to ensure smooth adoption and impactful results.

1. Data Fragmentation

“Logistics operations generate vast data from warehouses, carriers, and tracking systems. When this data is siloed and inconsistent, AI struggles to produce reliable insights, creating inefficiencies and operational blind spots.” (Samuel et al., 2025)

2. Scalability Issues

Implementing AI at a small scale may work, but scaling across global supply chains demands significant resources. Infrastructure, bandwidth, and model optimization challenges often hinder seamless expansion and adoption.

3. Regulatory Compliance

Logistics involves cross-border operations, each with unique regulations on data use, privacy, and AI ethics. Ensuring compliance across jurisdictions becomes complex, risking fines, delays, and reputational damage if mishandled.

4. Operational Integration

Many logistics companies rely on outdated or fragmented legacy systems. Integrating generative AI requires costly upgrades, retraining staff, and re-aligning workflows, making implementation slower and resource-heavy for organizations.

5.Trust & Transparency

Generative AI models often act as “black boxes,” making it difficult for stakeholders to understand decision-making. Lack of explainability reduces trust, slows adoption, and complicates accountability during disruptions.

How Gen AI Can Enhance Logistics Management

Generative AI isn't just reshaping logistics management; it's actually making smarter forecasting, seamless communication, adaptive planning, and real-time optimization possible. With its model, it can power applications like simulating disruptions, automating documentation, and ultimately building resilient supply chains and inventory management.

Businesses can implement such tools to reduce costs, minimize risks, and enhance customer satisfaction, even with limited resources. The key is to start small, adopt AI for one process, like route optimization or demand forecasting, and scale gradually.

By embracing Gen AI strategically, decision-makers not only future-proof logistics operations but also gain a competitive edge in efficiency, agility, and customer-centric service delivery, encouraging you to build autonomy in market.

Is your logistics strategy ready to harness Generative AI for smarter forecasting, cost savings, and resilient supply chain performance? Talk to our experts at engineers at Centrox AI, and let's find the best solution for your daily logistics challenges.

Muhammad Haris Bin Naeem

Muhammad Harris Bin Naeem, CEO and Co-Founder of Centrox AI, is a visionary in AI and ML. With over 30+ scalable solutions he combines technical expertise and user-centric design to deliver impactful, innovative AI-driven advancements.

Do you have an AI idea? Let's Discover the Possibilities Together. From Idea to Innovation; Bring Your AI solution to Life with Us!

Your AI Dream, Our Mission

Partner with Us to Bridge the Gap Between Innovation and Reality.